Electron Beam Welding (EBW): How it works and why it’s better

From wafer-thin diaphragms to rocket motor housings, electron beam welding has the ability to join a diverse range of components in all shapes and sizes and in a multitude of material combinations.

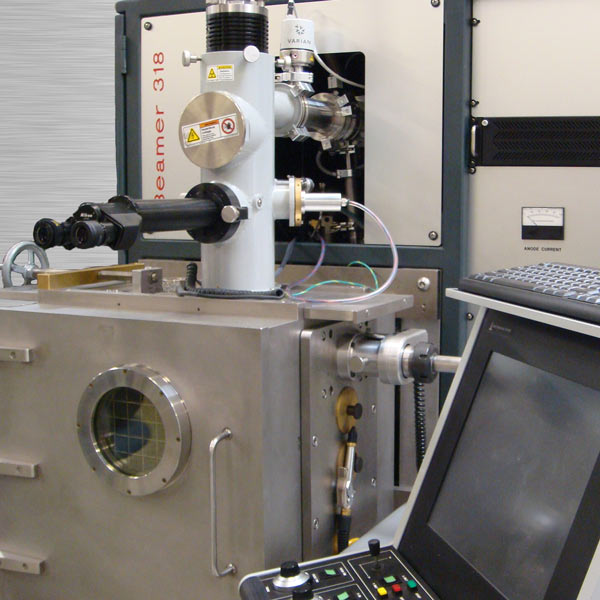

EBE Welding Machine with 12" Vacuum Cube

Some of the other benefits of an electron beam weld include:

- Localized heat input resulting in minimal distortion

- Fast welding speeds

- Narrow weld zone

- High depth to width ratio

- Small, localized Heat Affected Zone (HAZ)

- Highly controllable weld parameters

- Very wide power range for shallow or deep weld penetration

- Clean, smooth welds that often require little or no post-weld machining

- The ability to access ‘down hole’ or confined spaces

Applications:

Electron beam welding emerged as a production process in the late 1950s within the aerospace and nuclear power generation industries. Since then, it has become a preferred technique for small precision parts requiring very high-quality welds in low carbon steel, stainless steel, aluminum, titanium, inconel and many other exotic alloys. Today, it is used in a diverse group of industries such as: aerospace, automotive, defense, communications, electronics, jewelry, medical, oil and gas exploration, semi-conductor, sensors, transportation and commercial uses. The process has proved very reliable and cost-effective in high volume production due to the advent of small vacuum chamber machines and high welding speeds.

How it works:

Electron beam welding is usually performed in a high vacuum to prevent dispersion of the electron beam and to eliminate all oxidization. The electrons are produced by an ‘electron gun’ which can be positioned on top of or inside the vacuum chamber. The gun is usually stationary and the work piece is moved using a linear table (with or without CNC) and/or rotary drive devices. As the electrons strike the work piece, their energy is converted into heat, instantly melting the metal. Since the electron beam is tightly focused, the effective heat input is much lower than that of traditional arc welding and therefore only minimally affects the surrounding material, resulting in with a smaller heat-affected zone. The intensity or power of the beam can be tightly controlled by varying the accelerating voltage, beam current and focus position. Higher beam current produces increased heat input and weld penetration, while higher travel speeds decrease the amount of heat input which reduces the weld depth. The diameter of the beam can be changed by moving the focal point with respect to the work piece. Focusing the beam below the surface will increase the penetration, while focusing above the surface will increase the width of the weld. The shape of the beam can also be changed with the use of a waveform generator.

As the weld is completed, the work piece cools rapidly. While normally an advantage, this can lead to cracking in high-carbon steel if precautions are not taken. Most metals can be electron beam welded, but the most common are stainless steels, super-alloys and reactive and refractory metals. The process is also widely used to perform welds on a variety of dissimilar metal combinations.